Notice: This page is old and has been archived

Please go to other navigation menus. These pages are for reference only

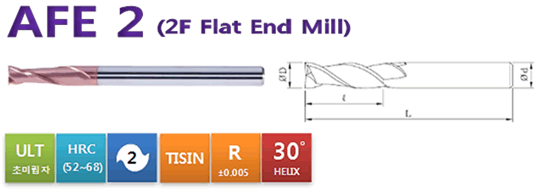

When high-speed cutting of hardened ceramic excellent performance. (52~68HRC).

Excellent wear resistance.

Precision tolerances applied to suitable for semiconductor, mold, electronics and precision machining.

excellent for high-quality, high-efficiency machining.

|

Size | D Tolerance | ||||

| D≦∅6 | +0 ~ – 0.01mm | |||||

| D>∅6 | +0 ~ – 0.015mm | |||||

| Order Number | Diameter RXD | Length of cut L1 | Overall Length L | Shank Dia d | ||

| AFE 2 010 025 040 S04 | 1 | 2.5 | 40 | 4 | ||

| AFE 2 010 025 040 S06 | 1 | 2.5 | 40 | 6 | ||

| AFE 2 015 040 040 S04 | 1.5 | 4 | 40 | 4 | ||

| AFE 2 015 040 040 S06 | 1.5 | 4 | 40 | 6 | ||

| AFE 2 020 060 040 S04 | 2 | 6 | 40 | 4 | ||

| AFE 2 020 060 040 S06 | 2 | 6 | 40 | 6 | ||

| AFE 2 030 080 045 S06 | 3 | 8 | 45 | 6 | ||

| AFE 2 040 100 045 S04 | 4 | 10 | 45 | 4 | ||

| AFE 2 040 100 045 S06 | 4 | 10 | 45 | 6 | ||

| AFE 2 050 120 050 S06 | 5 | 12 | 50 | 6 | ||

| AFE 2 060 120 050 060 | 6 | 12 | 50 | 6 | ||

| AFE 2 060 120 080 S06 | 6 | 12 | 80 | 6 | ||

| AFE 2 080 190 060 S08 | 8 | 19 | 60 | 8 | ||

| AFE 2 100 220 070 S10 | 10 | 22 | 70 | 10 | ||

| AFE 2 120 260 075 S12 | 12 | 26 | 75 | 12 | ||

| AFE 2 140 260 080 S14 | 14 | 26 | 80 | 14 | ||

| AFE 2 160 350 100 S16 | 16 | 35 | 100 | 16 | ||

| AFE 2 200 400 110 S20 | 20 | 40 | 110 | 20 | ||

| AFE 4 010 025 040 S04 | 1 | 2.5 | 40 | 4 | ||

| AFE 4 010 025 040 S06 | 1 | 2.5 | 40 | 6 | ||

| AFE 4 015 040 040 S04 | 1.5 | 4 | 40 | 4 | ||

| AFE 4 015 040 040 S06 | 1.5 | 4 | 40 | 6 | ||

| AFE 4 020 060 040 S04 | 2 | 6 | 40 | 4 | ||

| AFE 4 020 060 040 S06 | 2 | 6 | 40 | 6 | ||

| AFE 4 030 080 045 S06 | 3 | 8 | 45 | 6 | ||

| AFE 4 040 100 045 S04 | 4 | 10 | 45 | 4 | ||

| AFE 4 040 100 045 S06 | 4 | 10 | 45 | 6 | ||

| AFE 4 050 120 050 S06 | 5 | 12 | 50 | 6 | ||

| AFE 4 060 120 050 S60 | 6 | 12 | 50 | 6 | ||

| AFE 4 060 120 080 S06 | 6 | 12 | 80 | 6 | ||

| AFE 4 080 190 060 S08 | 8 | 19 | 60 | 8 | ||

| AFE 4 100 220 070 S10 | 10 | 22 | 70 | 10 | ||

| AFE 4 120 260 075 S12 | 12 | 26 | 75 | 12 | ||

| AFE 4 140 260 080 S14 | 14 | 26 | 80 | 14 | ||

| AFE 4 160 350 100 S16 | 16 | 35 | 100 | 16 | ||

| AFE 4 200 400 110 S20 | 20 | 40 | 110 | 20 | ||